Worldwide Load Testing Specialist (WWLTS) is the highest ranked Lifting Machine Entity in Africa. This is according to the South African Department and Employment and Labour – after our systems and procedures were audited. It was noted that WWLTS has an advanced and comprehensive inspection and reporting system that sets us apart from other Lifting Machine Entities and led to WWLTS being awarded the broadest LME Scope in the country.

WWLTS was previously known as Water Weights in South Africa, which was founded by the Graham family in 1979 in South Africa – originally under Spectrum Engineering brand in Benoni, South Africa.

The companies founders Mr J D Graham & Mr N D Graham were a true pioneers of the lifting industry in Africa, and managed to establish a distributorship for Africa with the IEMS Group in Aberdeen Scotland, which was known as Water Weights.

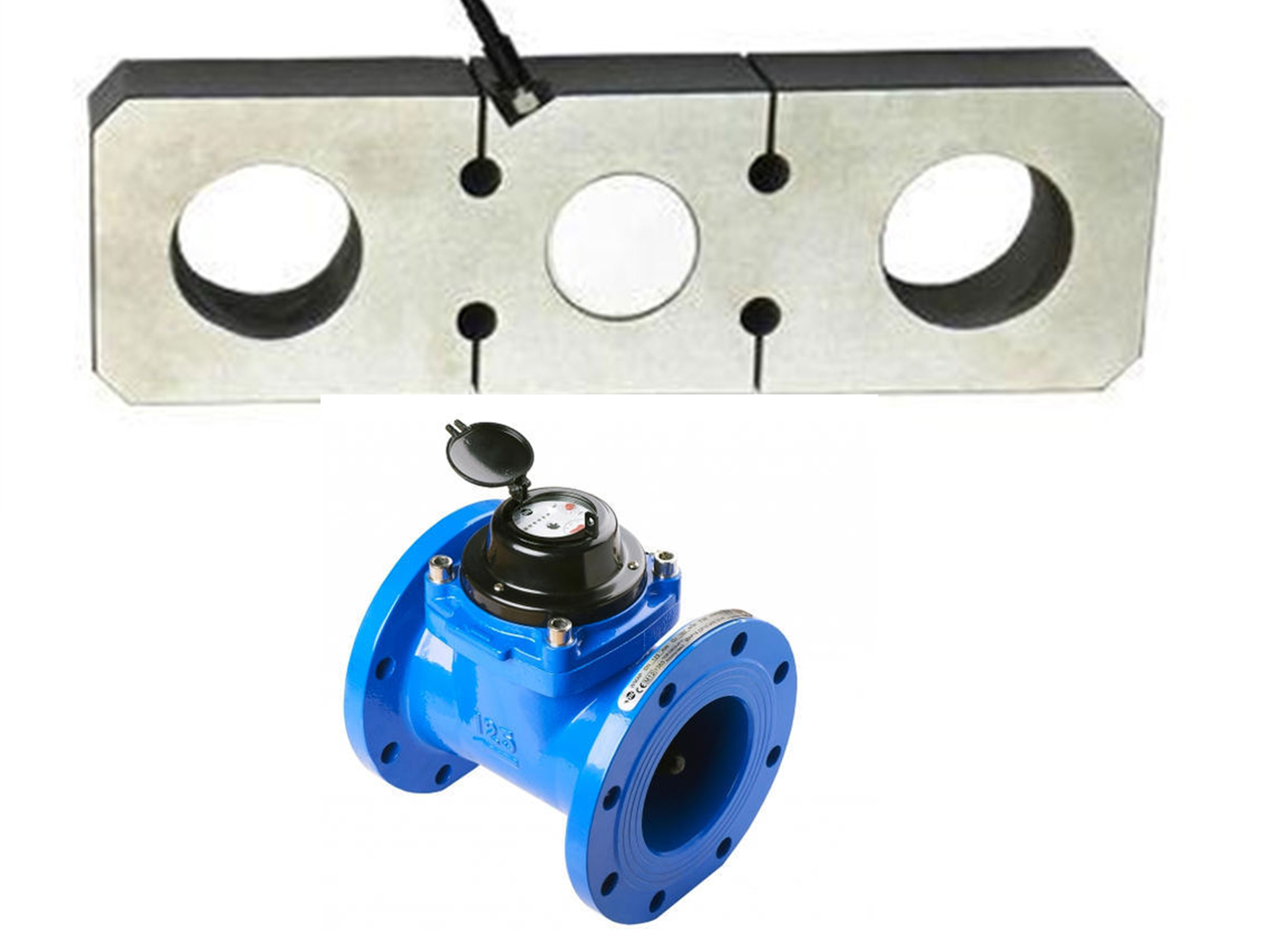

While there is place for both solid weights and water bags depending on site policies and access to space and water – we always recommend using water bags, as it is safer, cheaper and prevents shock-loading. In todays day and age we know the preservation of water is essential that is why we recommend ensuring we have a system that water can be pumped back into after use.

In the early 2000’s Mr J D Graham and Mr N D Graham were able to be apart of the founding members of what now is known as the Lifting Equipment Engineers Association of South Africa, which was originally modelled with their guidance on the Lifting Engineers Association (LEEA) of Great Britain’s principles, under the Graham’s guidance following their training under Water Weights UK and LEEA.

In 2018 Water Weights was acquired by the Dubai based – Unique Group and the Graham family opted to move away from the Water Weights Brand

WWLTS has since establish a sole distribution agreement for Africa with one of the original manufacturers of the proof load test water weight bag – JW Auto Marine based in the United Kingdom. This means that we can offer European standard proof load test bags from 0,25T – 100T and air lift marine salvage bags at competitive prices to the African Market. The data sheet specifications for our bags are available at our store website which is – www.loadtestbag.com

WWLTS has over 3 generations managed to acquire a stock holding of over 1340 Tons of Water Weights Bags, over 160T of solid weights, over 80 load cells between branches and other specialized equipment that enables us to be the specialists and the most qualified LME in Africa.

With millions of Rands invested in equipment alone it goes to show that this entity is committed to ensuring safety on site, which our norm and never compromised.

We ensure our technicians are highly trained and qualified and our equipment is the best the world has to offer.

Water bags are very cost effective as transportation costs are minimized – as an example if we were required to move 70 Tons of solid weights from point A to point B in order to test we would require 2-3 Super-link trucks – which is extremely costly – and thus the beauty of well engineered and specialised industrial proof load test bag were born. Making it possible for us to put 2 x 35 Ton bags onto one light delivery vehicle and elevating the logistics cost. Although the bags are extremely costly – it is all in the interest of safety to ensure the bags are manufactured to the highest quality. We recommend the bags comply with European Standards and come with a drop-test certificate for quality assurance. By using water bags to test lifting equipment it allows the tester to increase the load in increments, this means the tester can monitor the load and the stress on the machine as tonnages increase and in the event of a detection of failure one can seizes increasing the tonnage and relive the machine of stress in order to avoid further damage of the machine. This would not be possible with solid weights as the machine would be shock loaded with the full tonnage and if failure occurs the load will more than likely drop and could result in injury to personnel on site, or damage to the machine.

While there is place for both solid weights and water bags depending on site policies and access to space and water – we always recommend using water bags, as it is safer, cheaper and prevents shock-loading. In todays day and age we know the preservation of water is essential that is why we recommend ensuring we have a system that water can be pumped back into after use.

Our technicians are all put under intense training and evaluated personally by our technical Director Mr N D Graham. Mr N D Graham has been trained through an apprenticeship through the IEMS Group – Water Weights in the United Kingdom under the Lifting Engineers Association of Great Britain. This ensures that the quality of our inspectors is by far a step above the rest and lets our management rest well knowing that we put our business in the hands of specialists that are not just certified but we can ensure they are qualified.

Because of our superior training abilities and our acquisition of essential equipment holdings we are able to specialize in both big and small lifting machines. No Job is too big or too small. From a 50KG Jib crane to a 500 T Overhead Traveling Crane we have done and can do it all with our equipment inventory. We also offer our clients far superior and comprehensive reporting systems that ensure preventative maintenance can be achieved as to ensure safety on site.

One must always question the integrity and competency of a Lifting Machine Entity that is able to produce a “ONE PAGE” certificate for the client and is able to state weather the unit is satisfactory or not. Reporting should be complete and thorough. A “One Pager” cannot be considered complete nor thorough and cannot be seen as being compliant with Occupational Health & Safety Act -Driven Machinery Regulation 18 – with reference to both sub-section 5 & 6.

WWLTS also has the best interests of every single one of our clients at heart. It is essential for any responsible persons to be informed of the legal liability that they hold as the equipment owner or person responsible for the machinery. We see many lifting entities misleading customers and offering a sub-grade service, cutting corners in order to save costs. For now nothing has gone wrong? For now yes, but we ensure our clients are never left exposed to any potential unsafe environments on site. Every end user or responsible person can rest easy knowing that we are on site and all work is being carried out as per DMR 18 and the relevant incorporated standards.

We inform all responsible persons of their obligation and legal liability that they hold with regards to the law, the Occupational Health and Safety Act, and their obligation to the users. The law is clear that it is the user/owners responsibility to ensure the equipment is inspected and tested as per the Driven Machinery Regulation. Many end users believe that because a registered LMI from a registered LME has carried out the inspections and testing that the work has been completed correctly. Unfortunately we have many unethical organisations and individuals that deviate from what the client has paid for and cut corners to cut costs – this is often as a result of not being competent for the equipment they are testing or having the incorrect equipment to test the equipment. Entities that own the correct equipment do not have to rent equipment in for testing – this means that entities with the correct equipment should be reasonably priced to complete the job. If an entity that does not have the equipment in their inventory manage to come in at a better price – it is advised the responsible persons witness the test and ensure standards are adhered to – as legal liability falls on the owner/user should an incident occur. This information needs to be known to the client and we ensure our clients understand this so that they know our company is looking out for their interests and will never compromise on safety.

We have specialized in many industries from mining, sugar mills, manufacturing and production in multiple business sectors, smelters, shipping, petroleum, cement, access rental, paper milling, but in the last 10 years focusing on port operations in Africa. We actively service all of the mentioned industries and 6 ports in Africa. We have through this managed to specialize in the inspection and load testing of all port equipment such as Mobile Harbour Cranes, Ship to Shore Cranes, Straddle Carriers, Rubber Tyred Gantries (RTG’s), Empty Container Handlers, Reach Stackers, to name a few. We are also the preferred load testing service provider to both original equipment manufacturers Liebherr and ZPMC in Africa.

WWLTS also boast the first African Lifting Machine Inspector in the country – Mr B Msweli was trained as an assistant in the 1990’s and later became an apprentice at Water Weights in Richards Bay, under the mentorship of Mr J D Graham, in Kwa-Zulu Natal in the early 2000’s and was registered as an LMI in 2007. Mr Msweli has been at our company for over 25 years. We make special mention of him because we value his service to not only our company, but our family and that goes for everyone of our employees alike.

WWLTS holds a high ethos of family and professionalism both are regarded as fundamental key values at our company – we say family first because as a 3rd generation company with most employees having worked in the organization and branches for between 10 – 25 years. We know that it is important to look after the people that look after you. Professionalism comes as a result of people waking up holding a brand close to their hearts as they know there is no doubt we will walk the walk every step of the way and make sure our entire family of staff contingent and their families come first. We believe that this is key to success. It is important to keep motivated, it is important to ensure all staff members are able to grow and improve their skills. That’s truly what sets us apart from the rest.

We want to see people improve and that’s what we do not have a high staff turnover, nor a brain drain. In a lot of lifting entities we hear of technicians coming and going and jumping between companies – this means that companies will be reluctant to enhance individuals skill sets and their skills will be limited to what they need to know rather than becoming specialists and growing skills on a daily basis – this is also why we believe our staff and inspectors have earned the title of lifting machine inspectorate specialists.